MOLDING AND PRODUCTION

As El Medical and R&D, In our 600m2 Mold and Production center in Dudullu organized industrial zone, We implement your projects under the supervision of our experienced team..

Molds are irreversible investments as you know.. Therefore, determining the right solutions in advance can provide a great advantage in terms of both money and time..

Our experienced team offers you more accurate and cost-effective solutions with the help of state-of-the-art simulation software..

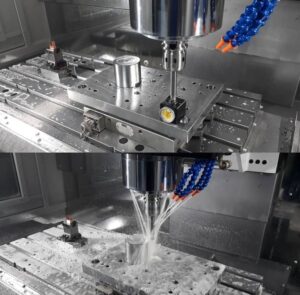

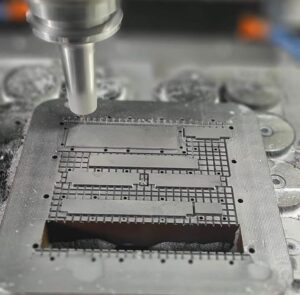

15 We transform our experience of more than years into the most accurate and economical solutions by using the latest technology software and CNC machines..

Pattern, from automotive with our production and design experience., We have implemented hundreds of products in many sectors of medical.

Simulation Mold Production Assembly…..

Design;

The design phase is perhaps the most important of all phases.. A wrong decision to be made at this stage can cost you a lot in the long run..

The experienced team of ELDE Medical and ARGE medical sectors will help you make the most accurate design decisions..

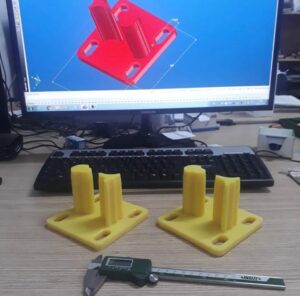

Simulation;

With state-of-the-art mold simulation software, we first test the operation of the molds of your designs in the computer environment, and we anticipate and take precautions against possible errors..

In this way, we achieve success in the first printing and offer you quality solutions in an economical way..

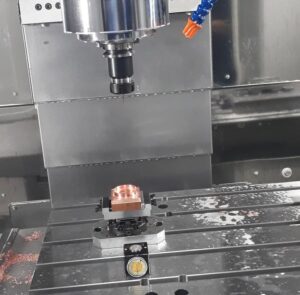

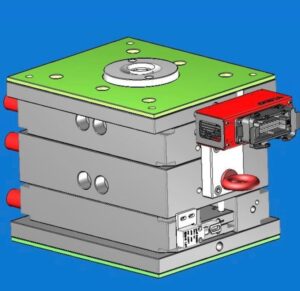

Mold design and production;

One of the most critical investments in the realization of a product is mold investment.. However, you can reach the desired result by working with the right team during the mold design and production phase..

Prefer a reliable team so that your mold does not turn into a dead investment.

Production and injection printing;

Quick test of your patterns, in order to be able to start production, to quickly realize your change needs over time.,

It is important that you can solve your mold production and injection needs in one place.. ELDE Medical and R&D offers you unparalleled flexibility.

fitting;

Assembly and packaging of your manufactured parts during or after injection can accelerate the time to market for the product., can reduce error rates and positively affect your overall costs.

We can always help you with our assembly team, the number of which increases or decreases according to the project needs..